Promotional Product Problems: 3 Things To Stop Your Promo Becoming An “Oh No!”

At Impact we’ve found that new clients fear their products will arrive and be nothing like what they envisioned. Thankfully there are measures we can take throughout the production process. These preventative steps will minimise the possibility of promotional product problems that require a dramatic fix.

We supply artwork proofs

As a part of the production process, we supply artwork proofs. These documents come from our factories and give you a visual representation of what your merchandise will look like. An artwork proof shows the size and position of your branding on the product.

Some of our factories have a disclaimer describing the slight variations that can occur in print colour and placement between products. These inconsistencies stem from the sheer number of products they are supplying. Their disclaimer covers them for the logo on one item being a millimetre or two off-centre where the logo on the next item is dead on.

Before the artwork proof, however, providing us all the information you can is the first step to making sure your merchandise is just right. Having a clear brief is integral. There are three more things you can do to limit promotional products problems.

Ask for a sample

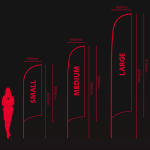

To further curb larger issues in branded merchandise, suppliers offer preproduction samples. These are at cost but are so important. Pre-production samples give you confidence – that what you will receive is absolutely what you want. A fully branded sample gives you a feel for the the product’s size and shape. If the sample arrives and the item is too heavy or a detail is off, we can easily make adjustments to ensure the product just right.

A sample also shows how the colours will appear when they’re printed. Sometimes the product texture and its base colour can alter the tone of the print once it’s applied to the surface. To counter this, suppliers print a layer of white first. This enables us to get a truer print. In any case, a pre-production sample will demonstrate the final result.

Our advice? Get a sample; for the peace of mind and avoiding buyer’s remorse, it’s worth it.

Know the PMS number

In the branding business we know that the colours of a logo are almost as important as the design itself. Cadbury Purple is not the same as purple, and purple will never be used on a Cadbury product.

The way to ensure the correct colours are used on merchandise is to use the specific Pantone colour, identified by a number/letter code. These colours are so important to the big brands that there have been decades-long battles over them and their use (don’t you dare use PMS 2685C for your chocolate bar wrapping, you will regret it).

If an exact colour is critical, know the PMS number. When it is requested and where printing and production allows, that is the colour that the factories will produce regardless of how it looks on your screen.

Order early

Our most common promotional product problems are clock-related. Deadlines multiply stress by 100x. While Impact can meet some extremely tight time-frames, our clients’ stress becomes our own when your deadline looms.

To stop a time-frame strangling the possibilities available to you, order early.

Know your events calendar and start looking at promotional products three to six months in advance. The options available increase when there is the time to make them and perfect the branding.

Getting in with plenty of time also reduces the worry of products getting lost in transit. We all feel the immense pressure when the courier has a tight delivery deadline. So, to prevent refreshing the courier tracking site every 10 minutes and a possible late arrival, order early.

Read more about promotional product time-frames.

What if I'm still having promotional product problems?

Mistakes do happen, no one is immune. Even if you’ve done all of the above and we’ve done everything our end, there is still a small chance that something could go wrong at any point in the production chain. If there’s still an problem with the product (it’s faulty, broken, the wrong colour or has wrong parts), there’s no problem that can’t be fixed with some time and effort. Products can be remade, parts re-sent and logos reprinted.

We are passionate about the products we produce and so are just as passionate about getting them right. Our experienced and knowledgeable team are only a call away to answer any questions before, during, and after the production process.